csem nano hardness tester|nanoindentation tester nht3 : discount store Film hardness and elastic properties can be derived using a CSM nano-indentation tester. Indentation testers are high precision instruments used for . Resultado da Para os que gostam de deixar o Counter-Strike sempre configurado da maneira que mais gostam de jogar, os comandos de inicialização são uma .

{plog:ftitle_list}

web2 dias atrás · Conoce aquí los resultados y números del sorteo de La Tinka del miércoles 28 de febrero, que tuvo un Pozo Millonario de S/9′269,691. Además, revisa los resultados y ganadores del Sí o Sí .

Film hardness and elastic properties can be derived using a CSM nano-indentation tester. Indentation testers are high precision instruments used for .

tool to compress gas springs

Flexible, user-friendly nanoindenter for modulus, hardness (Oliver-Pharr analysis, ISO 14577), storage and loss modulus, and universal testing. Capable of exerting up to 1N of force to test hard materials at higher loads and larger . Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness .Hit 300 is the simplest-to-use nanohardness tester on the market, featuring automated measurements, high accuracy, and a unique laser targeting system at a competitive price. . Hardness and elastic modulus of coatings can only be .

Scanning electron microscope picture of an array of nano cones. Each nano cone is located inside a nano cavity. . Nanox intends to build tubes with CSEM chips in them, for testing and validation in the next stage. The . To do this, friction and wear tests were done using Tribotester, S/N: 07‐128 CSEM machine. Also, hardness variation was determined by means of CSEM Nano‐Hardness Tester S/N: 4‐113. It was seen that hardness was increased in TiN and Tinalox coated substrates, while friction coefficient and wear rate decreased.SUMMARY 6.1 Static hardness testing involves instruments capable of the following range of indentation forces: atomic force indentation (AFM) nanohardness (TriboIndenter) ultramicrohardness (UMIS) microhardness (Knoop, Shimadzu) bulk hardness (Rockwell, Brinell) (1 pN to1 µN) (1 µN to 1 mN) (1 mN to 1 N) (100 to 103 N) (103 to 104 N) 6.2 .

Bruker's mechanical testers and tribometers provide the most comprehensive and versatile means of investigating tribology—friction, wear, load, hardness, and lubrication. Measuring friction, wear, and material mechanical properties is a way for engineers to understand how materials, coatings, and lubricants will stand up to the rigors of .

Nano Scratch Tester: NST³ . Revetest Scratch Tester: RST 300 . Showing to of . Adaptable comprehensive mechanical tester. With the versatile modular Step platforms, a broad force range is covered for scratch testing, conventional hardness testing, and instrumented indentation. Seamless transitions between these methods are possible without the .

This unique feature automatically detects and measures the area of the imprint of a conventional Vickers test and eliminates user influence on the Vickers hardness test results. The RST 300 and other Anton Paar scratch testers are the only scratch testers on the market with such advanced capabilities in conventional Vickers hardness testing.

In a depth-sensing indentation hardness test, a diamond tip is pressed into specimen till a given maximum depth or load and then removed, synchronously the load on, as well as the displacement of, the indenter are recorded. . Nano-indentation hardness was measured on a nano-indenter (CSEM, Instruments, Switzerland) by a Berkovich type diamond .CSM Instruments has been leader in the development of instruments for surface mechanical properties characterization for over 30 years in both research and industrial fields. Our product line includes: • Scratch Testers: Used to measure characteristics such as adhesion of a coating, delamination effects or cracking in order to optimize coating techniques and determine failure .The Vickers hardness testing method offers advantages such as a small indentation size, accurate hardness measurements, and applicability to a wide range of materials. Series measurements or mappings are very often carried out using this met-hod. However, it may not be suitable for very soft or highly textured materials, while alternative .

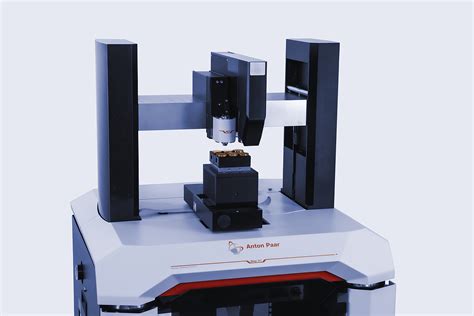

Investing in a DuraScan G5 hardness tester significantly reduces costs in the laboratory. The fast preparation of your testing tasks, the saving of templates for identical parts, many automated processes and the fully automatic testing process shorten the time required for hardness testing and therefore save money every day.Anton Paar's portfolio of instrumented indentation testers employ a wide range of forces and thus represent the most versatile and applicable solutions on the market. Covering nano-, micro- and macro-indentation, the testers allow for studies on countless materials, including metals, ceramics, semiconductors, and polymers.

Fischerscope – Nano-Indenter; Mitutoyo – profilometer for surface roughness tester; Phase II Rockwell hardness tester for coating adhesion and substrate hardness checks; CSEM Calotest – coating thickness verification; Metro-Cad 100X binocular microscope; Minolta color spectrophotometer - For color analysis on decorative coatings. Hardness and Young's modulus were evaluated by measurements with the nano hardness tester (NHT) utilising a Berkovich diamond tip (triangular). This instrument was commercialised by CSEM Instruments (Switzerland) [18] for indentation of thin films utilising a differential capacitive measurement technique. For thin films, the indentation has to .Sample load/depth curve generated by the Nano-Indention Tester Film hardness and elastic properties can be derived using a CSM nano-indentation tester. Indentation testers are high precision instruments used for the .The Nano Tribometer (NTR) Nano Tribometer In Nanotribometry, a flat, a pin or a sphere is loaded onto the test sample with a precisely known force.The friction coefficient is determined during the test by measuring the deflection force on the arm. Wear coefficients for the pin and disk materials are calculat.

CSM Instruments SA originally started as a spin-off of CSEM (Centre Suisse d’électronique et de microtechnique) in 1999 after several decades of developing instruments to characterize mechanical properties of material surfaces at the micro- and nano scales.

Surface characterisation by nano indentation and nano scratch method to determine hardness and adhesion of coating.previously CSEM Instruments

nanoindentation tester nht3

The hardness of the coatings were tested on a CSEM nano-hardness tester with a Berkovich diamond intender. Hardness values were obtained from analyses using the Oliver-Pharr scheme. The hardness of the nanostructure coating increases from about 3.5GPa up to about 6.8GPa when the aluminium concentration increases from zero to 47at.%. The hardness and Young′s modulus of the coatings were evaluated from nano-indentation measurements made on the CSEM nano-hardness tester. The data were obtained for a load of 50 mN. The depths of all indents were less than 10% of the coating thickness. For the coating deposited at 200 V, no data could be collected due to substantial .Nanoindentation is vital for revealing the quantitative mechanical properties of small volumes of materials. Currently, this method is a standardized method for determining plastic, elastic, and visco-elastic properties of materials such as ceramics, biological materials hard thin films, soft films, multi-phase metals, semiconductors, and plastics on a micron to nanometer scale.

The SAECO Lead Hardness Tester measures alloy hardness by determining the depth of penetration of a hardened steel indenter into a bullet. Relative hardness of the bullet is read off a vernier scale. The vernier scale is calibrated in arbitrary units from 0 for pure lead up to a SAECO hardness of 10. We have found that a SAECO hardness of at . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed. . The basic components of a nano hardness tester can be divided into several parts, including the control system, moving . The hardness of the samples was measured with a CSEM nano-hardness tester. The applied load was 100 mN. The hardness of the unmodified substrate was measured as 710 Hv. The hardness of the samples modified by the micro-pulsed plasma nitriding process was 1200 Hv and the hardness of the plasma nitrided + N ion implanted samples was 1500 Hv. . Starrett Benchtop Hardness Testers are advanced measuring instruments designed for accurate and reliable hardness testing in a variety of industrial and manufacturing applications. With user-friendly software and advanced features such as data output and programmable load and dwell times, these testers provide unparalleled precision and efficiency.

The nanomechanical properties e.g., nanohardness and Young׳s modulus of the ITO film were evaluated by the nanoindentation (CSEM Nano-hardness tester) technique utilizing a Berkovich indenter at three different loads e.g. 1, 2 and 5 mN.

nanoindentation tester

webThe latest tweets from @AngelNayl

csem nano hardness tester|nanoindentation tester nht3